OUR PRODUCTS

Thermal insulation coating

Bronya Light Airless North NF

Basic product, applied like paint – acts as a thermal barrier!

[ninja_form id=3]

Bronya Light Airless North ultra-thin thermal insulation

It has thermal insulation properties similar to the main line, but in addition to high quality microspheres, it contains a highly porous nanogel which has thermal insulation and vibration damping (soundproofing) properties.

The material is used at temperatures from –60 ° С to + 150 ° С

Bronya Light Airless North thermal insulation coating is a unique building material based on the use of the latest thermal insulation components.

Bronya Light Nord Modification Update

During the production of the Bronya Light Airless North modification, the recipe was significantly improved, the material is produced in 10 and 20 liter containers (traditionally the price for 1 liter in all types of containers is the same), its properties thermophysics and physics are enhanced. In addition, Bronya Light Airless North, as well as other modifications, has a certified release form with an NF (non-combustible) flammability group.

In the Bronya Light Airless North Updated Mod video you will see:

- Container types

- Mixing material

- Application of Bronya Light Airless North by an airless spray device

- Application of Bronya Light Airless North on the ZHKTM Bronya series

- Application of Bronya Light Airless North with a brush

- Measurement of thermophysical properties of Bronya Light Airless North (comparison with basic modifications of ZHKTM Bronya series)

Summary table of measurement results

| Modification | Classic Armor (1,5 mm) | Bronya Facade (1,5 mm) | Armor Light Airless North (1,5 mm) |

|---|---|---|---|

| base t° | 128 | 126 | 130 |

| surface temperature | 47 | 47 | 57 |

| *Thermal conductivity | 0,001 | 0,0012 | 0,0022 |

* Thermal conductivity of the material based on normative and mathematical calculations, based on the thermophysical indicators of these measurements.

The thermophysical properties of the renewed Bronya Light Airless Nord thermal insulation putty have reached a new level and have approached the indexes of the basic modifications of Bronya thermal insulation!

Bronya Light Airless North is compatible with all ZhKTMs (including competing brands), and due to its innovative composition can in most cases be used instead of ZhKTMs (thermal physics is an order of magnitude more higher than other similar products).

Where application of 3mm Bronya Classic or Bronya Facade is required, you can now only apply the first and last coats with basic modifications (Classic or Facade), and “compound” the remaining thickness with Light. Thus obtaining a layer “cake”

Measurement of thermophysical parameters Bronya Light Airless North + Bronya Classic

| Measuring point | surface t ° C |

|---|---|

| Electric cooker surface | 145 ° C |

| 1mm Classic Armor | 55 ° C |

| Armor Classic 1 mm + Armor Light Airless North 1 mm | 55 ° C |

| Armor Classic 1 mm + Armor Light Airless North 1 mm + Armor Classic 1 mm | 45 ° C [!] |

| 3mm Classic Armor | 47 ° C [!] |

From the results obtained, we can conclude that the Bronya Light Airless North modification does not alter the thermophysical properties of the Bronya Classic base modification when using the scheme – 1 mm ZHKTM + 1 mm Bronya Light Airless North, and when using the 1mm ZHKTM + Bronya Light Airless North 1mm Scheme + 1mm Heat Insulation even improves them. This is achieved by the fact that airgel powder voids included in Bronya Light Airless North do not level out the non-linear dependence of layer thickness. The main thing is that Bronya Light Airless North is located between the two layers of thermal insulation.

Bronya Light Airless North putty can be applied with a spatula, trowels, plastering machines, perfectly levels surfaces being a topcoat in its own right!!!

But when 10%-15% distilled water is added, Bronya Light Airless North turns into a liquid heat insulator and can be applied with a brush!

At the same time, the thermophysical properties are slightly lower than those of the basic modifications. But at the same time, it is higher than that of the cheap counterparts that have flooded the market.

And with all the physical and thermophysical parameters, the price of Bronya Light Airless North is much more cost-effective.

The uniqueness of the Bronya Light AirLess North thermal and acoustic insulation coating is that our material has inherited all the positive properties of “nanogel”, while expanding and complementing the scope and functionality.

Request a free sample and view our listed specifications!

You can familiarize yourself with the Bronya Light Airless Nord instructions in the Technical Documentation section.

Ultra-thin thermal insulation Bronya Light Airless North NF

Bronya Light Airless NF modification, identical in release form and packaging, with a low-fuel (base) modification.

It is important to note!

To date, we are not aware of similar thermal insulating coatings with proven non-combustibility (NF) and thermal conductivity similar to our basic modifications – full competing analogues of these modifications from other manufacturers of products from thermal insulation especially in the economy segment, which became possible due to the successful substitution of import components.

But on the market there are:

- Non-combustible coatings with an NF certificate, including those of manufacturers of thermal insulation materials with a certain (or without) thermophysical effect, offering to apply on their basic (G1) modifications (by the way, without confirmation of thermal conductivity ) in order to supposedly obtain a final thermal insulation coating with NF certification

- NF certified thermal insulation material, but whose declared thermal physics is 2 to 8 times greater than “one thousandth” (essentially without any legitimate proof of thermal conductivity)

Learn more about the Bronya Light Airless North modification

Bronya Light Airless North is non-toxic, does not contain harmful volatile compounds and is also completely safe for allergy sufferers, which is confirmed by the conclusion of the sanitary-epidemiological examination issued by the Center for Hygiene and Moscow FBU epidemiology. .

The special composition of heat and sound insulation Bronya Light Airless North allows you to perform plastering and heat insulation work on the facades of buildings and structures at the same time, reducing labor costs and shortening working time. Bronya Light Nord Airless thermal insulation coating has high adhesion, vapor permeability, weather resistance and durability.

The use of Bronya Light Airless North thermal insulation coating in production premises and workshops allows to increase the energy efficiency of the company and to reduce the costs of heating or cooling the premises, which will reduce the production costs and improve working conditions. In addition, it has the ability to be used on equipment used in maritime navigation

Bronya Light Airless Nord démonstration de la facilité d’application et comparaison avec Bronya Façade

BRONYA LIGHT AIRLESS NORD est conçu pour être utilisé dans la construction, la reconstruction et la réparation de bâtiments résidentiels, civils et publics, à des températures ambiantes négatives de +30 ° C à -35 ° C. Cette modification a une faible fluidité newtonienne, par conséquent, lorsqu’elle est appliquée sur des surfaces verticales, il n’y a pratiquement pas d’effet “fluage”, même lors de l’application d’une couche d’une épaisseur de 1 mm ou plus. En outre, le matériau a une perméabilité à la vapeur accrue et peut être utilisé pour isoler les structures enveloppantes de bâtiments et de structures. La température de fonctionnement de la modification BRONYA LITE AIRLESS NORD varie de -60 ° C à +90 ° C.

Dans un proche avenir, attendez-vous à des photos et vidéos supplémentaires de tests de ces modifications

Distinctive features of Bronya Light Airless North

A distinctive feature of Bronya Light Airless North from other modifications of the Bronya series is:

- The use of thermal insulation coating is more cost-effective (to solve additional insulation problems) than almost any insulation, because the cost of Bronya Light Airless North is proportional to that of ordinary plaster mixes.

- Application on surfaces where it is necessary to solve the problem of light insulation (to eliminate the effect of a cold wall, frost or condensation in severe frosts), as well as where the thermophysical properties would require less than 1 mm of Bronya thermal insulation (Facade or classic)

- Applications in multilayer enveloping structures, with the possibility of applying any construction material on our coating;

- Simultaneously perform puttying and thermal insulation work, which will significantly reduce labor costs;

- Possibility of application by coating machines and high-pressure airless spraying devices;

- Layer thickness up to 3 mm in one pass;

- Acceleration of the drying process when the temperature rises to 50-60 ° C;

- Mixing with a construction mixer at any speed is permitted;

What could not have been done before is now possible with Bronya Light Airless North !

1. Thermal insulation of floors according to the warm floor system.

Standard methods of underfloor heating installation require insulation between the floor slab and the heating elements of the system, which significantly increases the thickness of the cake. Now you no longer need to use standard insulation materials, which eventually lose their strength, Bronya Light Airless North is able to perform thermal insulation work better than any other material and significantly reduce the thickness of the hot ground.

Light Bronya Airless Nord will create a thermal barrier, preventing the flow of cold from the outside and reflecting the heat coming from the heating system.

2. Building walls will be insulated and coated in one step with Bronya Light Airless North.

Insulating the walls of buildings is a rather complicated and time-consuming process, which cannot always be done with traditional building materials, which are noisy and require additional labor during installation. All decorative materials such as wallpaper, paints, decorative plasters, tile adhesive, etc. can be applied over Bronya Light coating.

3. Roof insulation.

Bronya Light Airless North allows you to insulate the roofs of buildings and structures using materials that do not weigh down the structure and at the same time create a thermal barrier from the external environment. Thus, there is no heat loss, internal icing, condensation and “ice formation” during the cold period, and heating during the hot period is significantly reduced.

Visual experiences demonstrating the quality of the thermal and acoustic insulation of the Bronya Light Airless North:

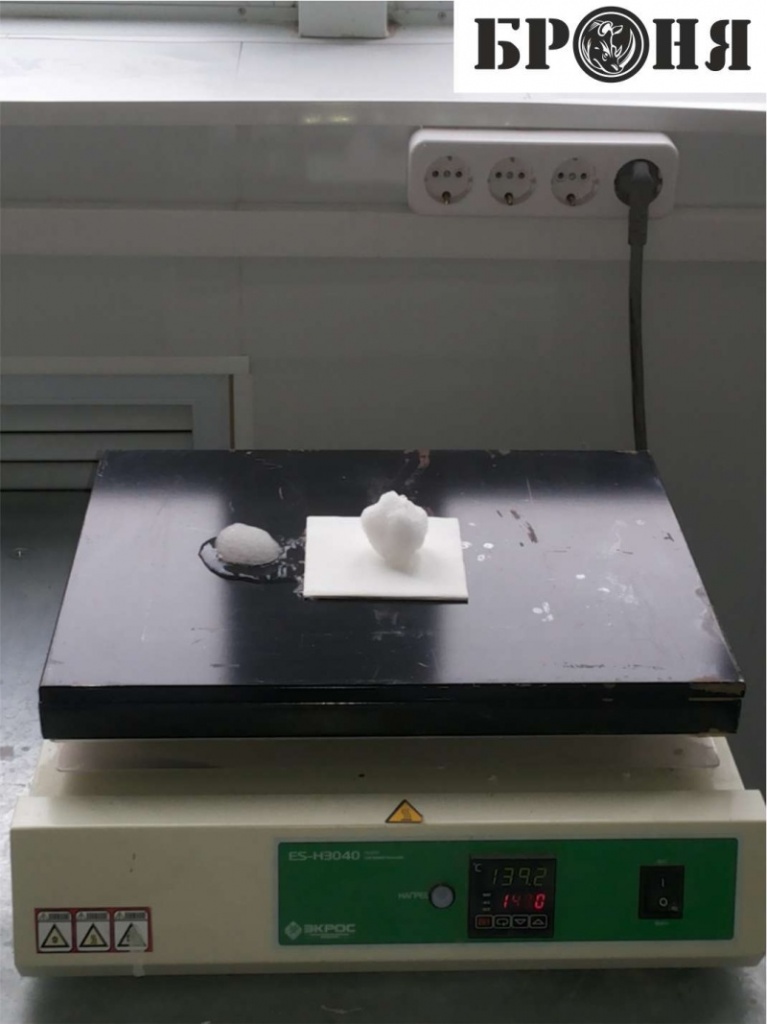

1. Apply 3mm thick heat insulation to half of the electric stove, after completely dry, turn it on. Place a block of ice and your hand on an insulated and uninsulated surface and you will see and feel the difference.

2. You can also perform a simple experiment – apply Bronya Light Airless North, for example, to a brick on one side with a thickness of only 1 mm, then after drying, take the brick in your hands from 2 sides (covered and no) and notice how the heat transfer has changed (the coated side removes significantly less heat from your hand). The same thing happens with the wall of the room.

3. Bronya Light Airless North is applied to the surface of the drywall, half of the drywall is left uninsulated to better visualize the possibilities of insulation. The plasterboard is placed inside the freezer with the treated side down, after which the chamber is cooled and the readings of the measuring instruments are taken. This experiment makes it possible to reproduce the real operating conditions of the enclosure structures of buildings and structures. The temperature in the freezer drops to -18°C, after which readings are taken on an insulated and uninsulated surface

| Indicator | Value, ºС | |

|---|---|---|

| Cold room temperature | 18 | |

| Ambient temperature | 25,6 | |

| Insulated area surface temperature | 19,2 | |

| Temperature at the surface of an uninsulated area | 7.4 | |

According to experience:

Bronya Light Airless North in building insulation

| Scope of Bronya Light Airless North | Benefits and effectiveness |

|---|---|

| Thermal insulation of building facades during new construction, reconstruction and restoration |

|

| Thermal insulation of internal surfaces of enclosing structures of residential and industrial premises |

|

| Thermal insulation of roofs of buildings and structures, roofs of metal sheds and garages, attic floors |

|

| Slopes of windows and doors, thermal insulation of loggias, balconies, protrusions of metal and concrete structures, ends of monolithic ceilings |

|

| Interpanel seams |

|

Figure. 2. Brick with Bronya Light Airless North applied

Figure. 2. Brick with Bronya Light Airless North applied